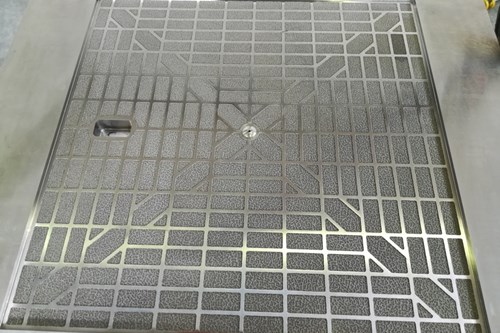

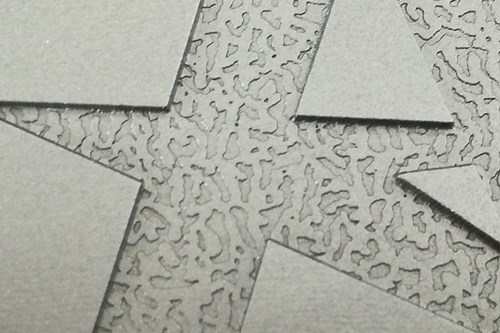

Our new laser technology offers advantages for the creation of textures and microstructures, markings and engravings in an efficient and repeatable way on objects in two or three dimensions.

We turn to mold manufacturers, mechanical workshops that require speed and quality of execution.

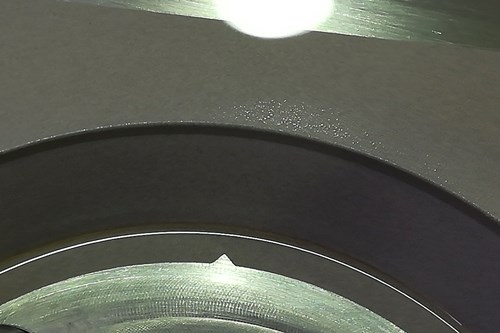

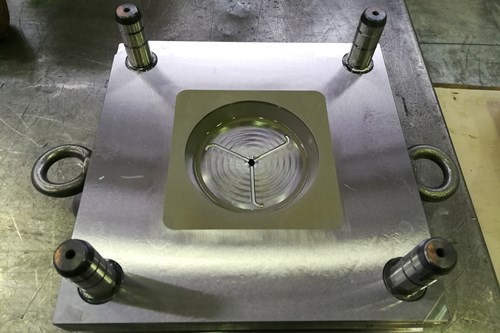

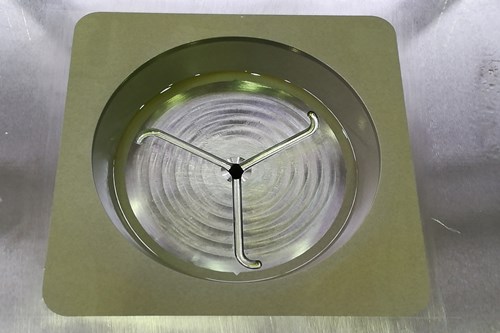

M.I.T. is able to create textures with complex 3D geometries, repeatable over time.

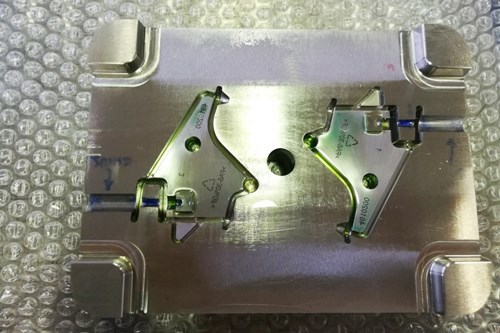

On request we realize the 3D model of the piece with consequent texture mapping for the creation of any desired 3D geometry.

We improve the image of your product thanks to textures that are always unique and therefore original in the results.

Compared to the traditional processing of the surfaces obtained by photoengraving, laser processing offers economic advantages, ecological and creative.

Our strength is in the speed of execution of the requested operations

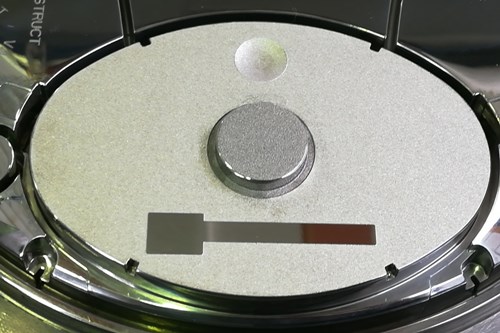

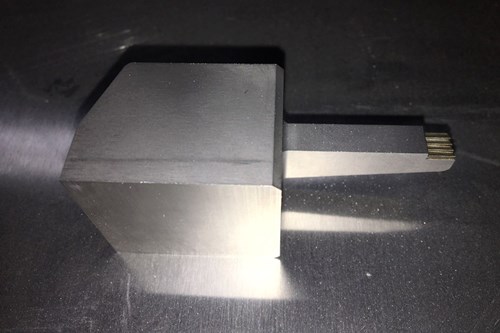

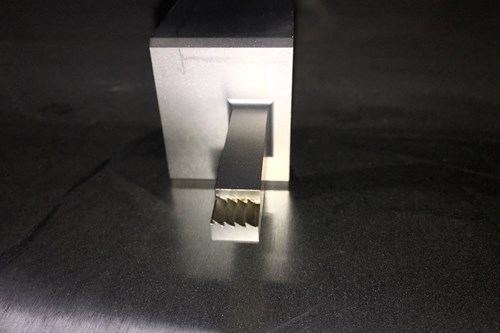

Laser engraving on copper/beryllium and graphite electrodes, materials that require particular Laser-work parameters.

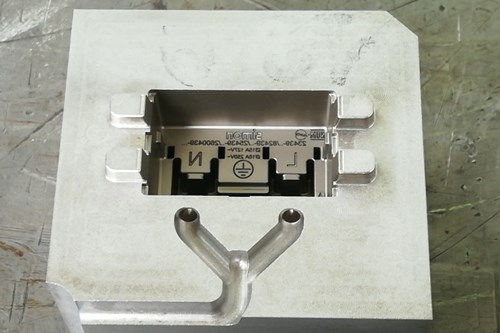

Creation of logos, codes plastic mold material, barcode - qr code for archiving and traceability of your pieces.

We produce mold nameplates anodized aluminum and not, you provide the model and we deliver the cut plate, perforated and laser etched with your order number, customer number, info mold construction and plant engineering.

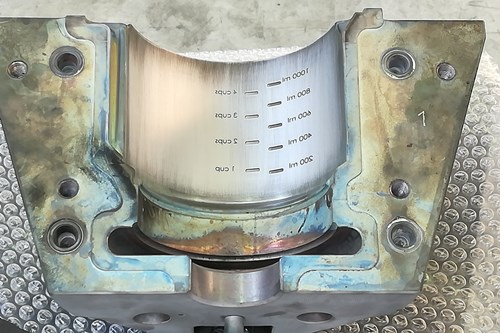

Our polishing department, with infinite experience, will know how to mix lapped print parts to areas where a particular texture is required, thus delivering the finished product, 100% repeatable even on multicavity molds.

Our laser texturing solution can give you that distinctive mark in 3D geometry in a wide range of industries, including automotive, electronics, packaging and mold making for products such as footwear and sporting goods.

5-axis CNC machining center for laser photoengraving. GF + pulsed 50W fiber.